In industrial projects involving large tolerances, structural deformations or frequent access requirements, static seals quickly reach their functional limits. In these cases, failures are rarely caused by material wear, but by the geometric inability of the sealing system to adapt to the real application.

Industrial inflatable seals introduce an active, on-demand sealing principle, solving problems that cannot be addressed with conventional passive solutions. This guide explains when to specify them and how to avoid the most common errors that lead to premature in-service failures.

1. When a static seal stops working

In real failure analyses, inflatable seals almost always appear as corrective solutions after recurring sealing problems that cannot be resolved by adjusting a conventional static seal.

- Loss of sealing due to excessive tolerances

- Variable structural deformations

- Frequent opening and closing requirements

- Inability to maintain constant compression

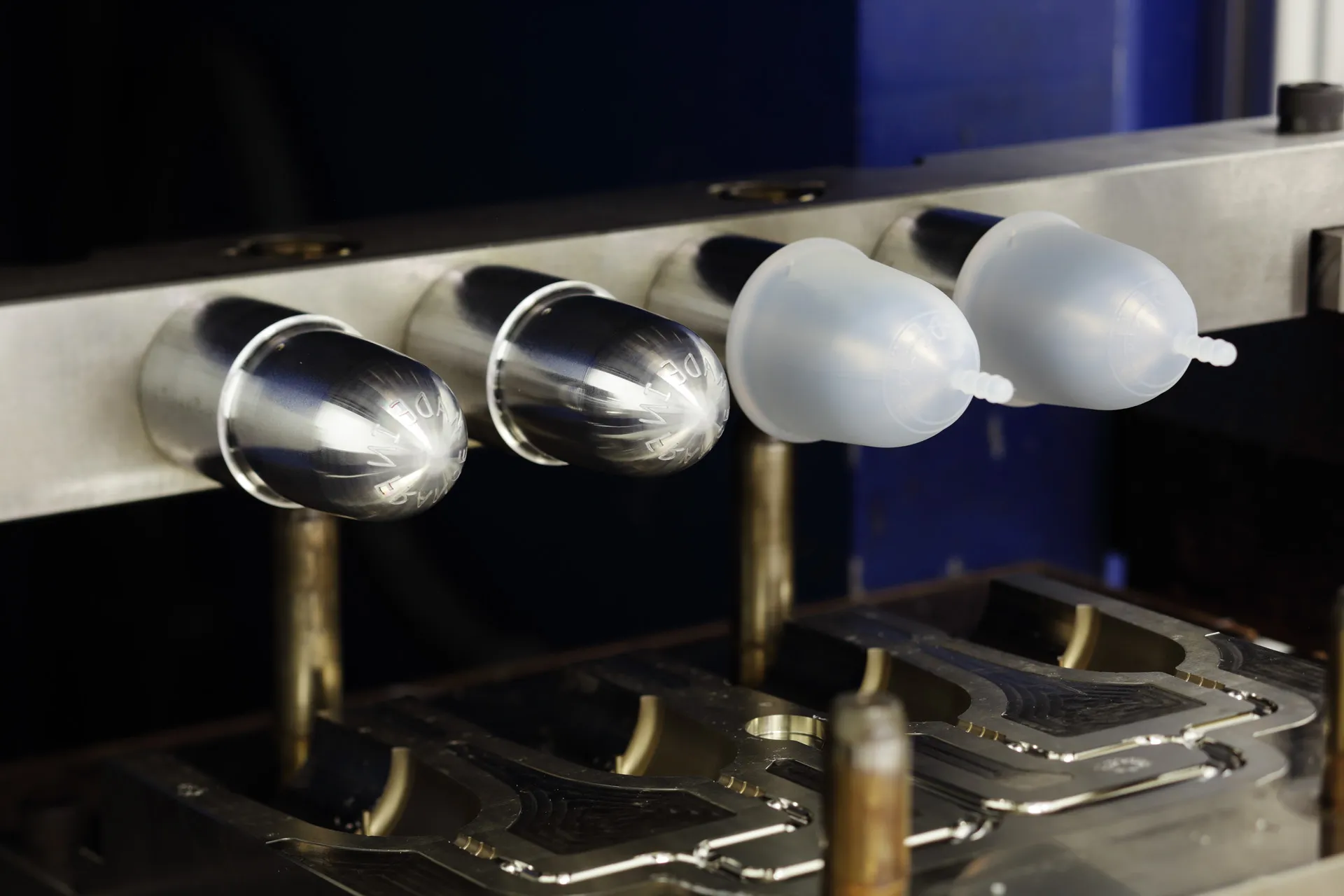

2. Operating principle: sealing under controlled pressure

Industrial inflatable seals operate in two clearly defined states, allowing the sealing function to be separated from system access or movement.

| State | Main characteristics |

|---|---|

| Retracted state (no pressure) | Allows movement, equipment access or part passage; compact profile with no interference; no permanent friction |

| Expanded state (0.5 to 8 bar) | Hermetic sealing by controlled deformation; uniform pressure distribution around the perimeter; adaptation to irregularities and deformations |

The inflation medium may be compressed air, water, nitrogen or inert gas, depending on safety requirements, chemical compatibility and the process itself.

3. TIXAN’AIR® profile selection: the issue is geometry, not the material

Each inflatable seal profile is designed for a specific pressure range, expansion capability and operating conditions. Incorrect profile selection is one of the most frequent causes of functional failures.

| Profile | Characteristics | Typical applications |

|---|---|---|

| HP – High Pressure | Inflation pressure up to 8 bar; limited expansion | Restricted space and demanding sealing |

| VV – Variable Volume | Large expansion volume at low pressure | Compensation of structural deformations |

| TGD – Très Grand Développement | Very large developments | Autoclave doors and industrial airlocks |

| BP – Basse Pression | Low pressure for general industrial use | Food processing equipment and standard machinery |

4. Mechanical properties of the system: why use EQ150, EQ160 and EQ170 compounds

TIXAN’AIR® inflatable seals manufactured with high-performance extrusion compounds ensure mechanical stability and repeatability, even under prolonged inflation and deflation cycles.

A critical point is the vulcanized closing weld of the profile, which prevents stress concentrations, maintains internal circuit tightness and allows thousands of inflation cycles without degradation.

5. The 5 critical installation errors (and how to avoid them)

| Error | Problem | Solution |

|---|---|---|

| Inflating the seal outside its housing | Permanent profile deformation | Fully install before pressurizing |

| Not cleaning groove and seal | Contamination prevents proper adhesion | Clean with 99% IPA before bonding |

| Rotating the valve on its base | Connection damage and internal leaks | Fix the valve before connecting tubing |

| Ignoring adhesive curing time | Premature detachment | Respect 12–24 h depending on ambient temperature |

| Applying tensile load during installation | Cross-section deformation | Handle without stretching and use suitable adhesive |

6. Industrial applications where they deliver real value

- Medical and pharmaceutical: autoclaves, sterilization equipment, ISO 8 cleanroom airlocks

- Aerospace and railway: access doors with on-demand sealing and EN 45545-2 certification

- Food industry: machinery with CIP cleaning cycles and FDA requirements

- Chemicals and instrumentation: controlled atmospheres and test chambers

- Marine applications: watertight hatches and compensation of structural movements

Technical conclusion

A properly specified inflatable seal solves problems that no static seal can absorb: compensation of extreme tolerances, reversible on-demand sealing, absorption of structural deformations and automation of access systems.

Does your application need to compensate movement or large tolerances?

Explore the full range of TIXAN’AIR® inflatable seals with detailed technical specifications and request engineering support.

Contact engineering →